News

Ningbo Hardchn bearing Co., Ltd.

Contact Us

Ningbo Hardchn bearing Co., Ltd.

ADD:No.501 Shizhu Rd, Linyu Foreign Investment Park, Jiaochuan Street, Zhenhai District, Ningbo city, China.

Tel:0086-574-86365365

Mobile:0086-(0)13858288142

Fax:0086-574-86454078

The reinforced sealing triangular outer spherical beari […]

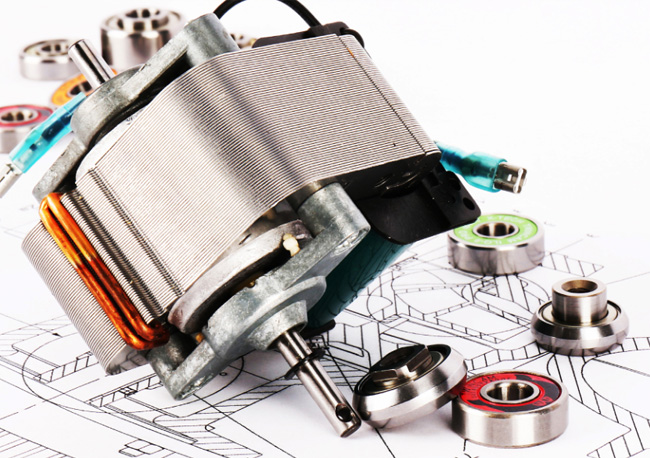

The reinforced sealing triangular outer spherical bearing structure is composed of a bearing seat, an outer spherical bearing, a cast dust cover and an oil seal.

Structural features of reinforced sealing triangle outer spherical bearing:

1. Adopt the structure of triangular outer spherical bearing with seat

In order to meet the structural requirements of agricultural machinery, the design adopts the outer spherical bearing type with a seat, which is composed of an outer spherical ball bearing and a bearing seat. The outer ring of this kind of bearing has a spherical outer diameter, which is the same as the concave spherical inner hole of the bearing seat. Cooperate, with automatic centering function, suitable for through shafts with poor rigidity and greater disturbance. The bearing seat is designed as a triangular cast bearing seat (Figure 2). The bearing adopts the AEL series outer spherical ball bearing with eccentric sleeve with automatic alignment, convenient installation and perfect sealing structure. The main feature of this type of bearing is that the bearing has a certain eccentricity at one end. Eccentricity, and the eccentric sleeve with the same eccentricity is matched with it.

Compared with the UC series outer spherical ball bearings with top thread, this type of bearing has a strong locking torque, and is especially suitable for agricultural machinery with long shafts and large windings. The bearing is equipped with a sealing ring and has good sealing performance. The bearings have been filled with high-quality grease when they leave the factory, which has good lubrication and anti-rust functions. It can also be added through the oil injection hole during use to effectively ensure the service life of the bearing.

2. Designed casting dust cover and oil seal

Due to the harsh environmental conditions of agricultural machinery, bearings require high sealing performance to ensure their use. For this reason, cast dust caps are designed on both sides of the triangular bearing seat (Figure 3). This kind of dust cover has high strength and can resist the impact of large hard soil and sand. Because there is a small gap between the shaft and the inner diameter of the dust cover, it can also effectively block large soil blocks and sand from entering the inside of the bearing.

The internal design of the dust cover is equipped with a sealed frame oil seal to strengthen the seal. Since the inner diameter of the oil seal is smaller than that of the shaft journal, there is a certain amount of interference. After the oil is sealed on the shaft, the pressure of its cutting edge and the contraction force of the self-tightening spring will produce a certain radial holding force on the sealed shaft to block the leakage gap. It can block the entry of soil, sand and water outside the bearing. The oil seal has the characteristics of small installation location, small axial size, compact structure, good sealing performance and long service life.